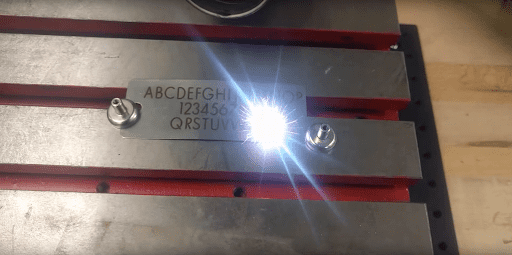

A laser engraver is a device that uses lasers to create designs or images on different surfaces. The laser beam is focused onto the surface of the material and the energy from the laser causes the material to change color or become damaged. Laser engravers can be used for a variety of purposes, including etching designs onto metal, wood, or plastic, and creating logos and graphics for signage and advertising.

Laser engravers work by directing a high-powered laser beam at a material. The material is usually placed on a moving table so that the laser can be directed across it in a precise pattern. As the laser hits the material, it removes small amounts of material, leaving behind a design or image.

Laser engraving is a popular choice for creating customized products because it is very versatile and can produce high-quality results. Laser engravers can be used to create intricate designs and detailed images that would be difficult or impossible to create using other methods. Additionally, laser engraving is relatively fast and easy to do, which makes it an ideal choice for businesses that need to produce large quantities of customized products quickly.

Things to Consider Before Choosing a Laser Engraver

If you’re considering getting a laser engraver, you should consider some things before making your purchase. Here are ten things to consider:

- Price is always important when making a major purchase. You can get the best laser engraver from a few hundred dollars to several thousand. If you’re on a budget, there are still great options available to you – just be sure to do your research before buying.

- The size of the engraving area is another factor to keep in mind. Some machines have very small working areas, while others can accommodate larger projects. Consider what kinds of projects you’ll be working on and choose an engraver accordingly.

- Laser power is measured in watts, and the higher the wattage, the more powerful the laser. More powerful lasers can engrave faster and deeper, so if speed is a priority, look for a machine with a high wattage. There are two main types of lasers used in engraving – CO₂ and fiber. CO₂ lasers are more common and tend to be less expensive, while fiber lasers are newer technology that offer some advantages in terms of speed and durability.

- The software that comes with your engraver will be very important in terms of ease of use and functionality. Some machines come with very basic software, while others have more robust options that allow you to do more complex projects. Be sure to compare the software offerings of different brands before making your purchase.

These are just a few of the things you should keep in mind when shopping for a laser engraver. With so many great options on the market, you’re sure to find the perfect machine for your needs. Just be sure to do your research and make an informed decision before buying. Thanks for reading!

Safety Measures When Using a Laser Engraver

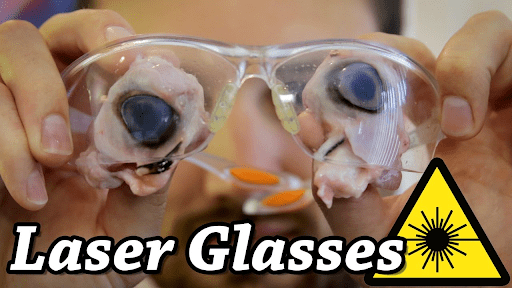

As someone who owns and operates a laser engraver, your top priority should be safety. Here are ten measures you can take to stay safe while using your engraver:

- Wear eye protection. This is non-negotiable. Always wear goggles or a face shield when operating the laser engraver.

- Keep the area well-ventilated. Lasers produce fumes that can be harmful if inhaled, so it’s important to have good ventilation in the room where you’re using the engraver.

- Don’t point the laser at anyone. Even if the beam is turned off, never point the laser at another person. Just because you can’t see the beam doesn’t mean it can’t hurt someone.

- Keep the laser beam away from reflective surfaces. Mirrors and other shiny surfaces can reflect the laser beam back at you, so avoid pointing the engraver at them.

- Be aware of what you’re engraving. Some materials, like aluminum foil, can be dangerous to engrave because they reflect light well and can cause the laser to bounce back at you.

- Turn off the laser when not in use. This will help prevent accidents and also prolong the life of your engraver.

- Unplug the laser when cleaning it. Don’t take any chances with electricity and water – always unplug the engraver before cleaning it.

- Keep the lens clean. A dirty lens will reduce the quality of your engraving and can also be a fire hazard.

- Regularly check for damage. Inspect your engraver regularly for any signs of wear and tear, and make sure to repair or replace any damaged parts.

These safety measures will help you use your laser engraver safely and effectively. Lasers are powerful tools that can be used for various purposes, from engraving wood to cutting metal. But no matter what you’re using it for, always take precautions to avoid accidents. By following these safety measures